Instrumentation is one of the major areas of Science & Technology which makes a great impact on vital sectors of national activities such as education, scientific research, industry, agriculture, medicine and health etc. The Department of Science & Technology (DST) has been promoting the area of Instrumentation through its Instrumentation Development Programme (IDP).

Objectives

The programme focuses on strengthening indigenous capability for research, design, development and production of instruments in the country leading to fulfillment of the following objectives: -:

- Indigenous development and production of instruments,

- Continuous updating of the technology of instruments to keep pace with technology improvements taking place globally, and

- Innovations in the area of instrumentation.

Activities supported under IDP:

Programmes to support and sustain development and production of indigenous and affordable instruments are evolved and supported under the IDP. The following types of activities are evolved and supported under IDP:

- Project support to scientists and technologists

- The Instrument/technology development programmes are supported with mandatory industry participation so as to facilitate easy absorption of technology and commercial production of the developed instrument/technology.

- Project Formulation

The following activities are supported under IDP for evolving well defined co-coordinated Research & Development projects involving Scientists/Technologists; Industries and Experts:- Cluster of Projects Meetings on identified Themes in Thrust Areas

- Brainstorming Sessions/Discussion Meetings in Specialized Areas of national importance

- Creation of National Facilities

Instrumentation hub is a theme based establishment for development of commercial models of laboratory prototypes developed in the laboratory as per industry/user specifications. It is proposed to be Industry friendly and will keep sustained interaction with relevant industries. Instrumentation Hub will house sophisticated facilities for prototype development, translational facility and a platform for technology incubation. It will also provide facility for batch production of laboratory prototypes for market validation. Facilities will be available on sharing basis to all the participating institutes/industries.

In all such cases, the host institute provides land, building, core manpower and thus maintains the facility. The host institute is also responsible for signing of bilateral MOU’s with participating institutes and will also serve as coordinating agency between DST and other participating organizations. The Host Institute will project the annual budgetary requirements to DST during the period of support. Steering Committee duly constituted by DST will regularly monitor the activities and progress of activities of the Instrumentation Hubs.- Sensor-Hub at CGCRI, Kolkata for commercial prototype development/ incubation of Solid State Sensors &Electronic Nose etc. (visit On Click Here)

- National Hub for Healthcare Instrumentation development at Anna University, Chennai for commercial prototype development/ incubation of Health Care Instrumentation (visit On Click Here)

Technologies Developed/ Transferred under IDP

- Membrane separation system for textile industry to reduce pollution by recycling developed at Synthetic &Art Silk Mills' Research Association (SASMIRA) and commercialized by M/s Permionics Pvt. Ltd., Vadodara

Number of Membrane filtration systems installed in Textile Industry Name and Address of Process House Type of Membrane Month Year Capacity

Litre/Hr% Recovery of water Remarks, if any CNATEX Processors Pvt. Ltd., Kongampara, Palakkad, Kerala R.O December 2011 15000 75% Waste water CLARIANT PAKISTAN,

PakistanU.F + R.O February 2012 30000 75 % Waste water CLARIANT PAKISTAN,

PakistanR.O February 2012 50000 75 % Waste water Wilhelm Textile India Pvt. Ltd., Delhi R.O April 2012 2000 75 % Dyeing process Tamil Nadu Textile Cooperative Mills, Erode N.F + R.O August 2012 50000 75 % Process Waste water Haren Textiles, Tarapur R.O October 2012 2000 75 % Waste water - A computerized instrument for measurement of fabric feel by nozzle extraction was developed by Department of Textile Technology, Indian Institute of Technology (IIT, New Delhi. M/s Texlab Industries, Ahmedabad, has already started marketing the instrument and they have got their first order from NIT, Jalandhar.

Screenshot of the webpage of the company marketing the Fabric feel Tester - Health & Physical fitness Monitor Developed at PSG College of Technology, Coimbatore

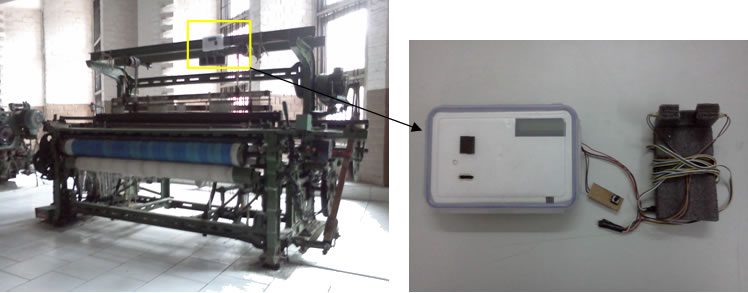

Multi-parameter monitoring equipment is designed & developed by PSG College of Technology. The Multi-parameter monitor systems will find wide applications in Hospitals - intensive care units, operation theaters, emergency and even in Ambulance. The equipment will be capable of measuring parameters like electrocardiogram (ECG), invasive and noninvasive blood pressure, pulse rate, pulse oximetry, body temperature, respiration rate, end-tidal CO2 and other specialized parameters. The equipment is integrated with sensors to measure, display and document physiological information about the patient. Currently, there is no indigenous manufactures of Multi-parameter monitors in India. Also, there is a need to develop cost effective indigenous multi-parameter monitors which will meet the hospital requirements both in urban and rural areas. The system will be an import substitute to international manufacturing. The technology was transferred to industry partner M/s. Pricol Medical System Limited, Coimbatore during March 2013. - E-pick Counter for Power Looms Developed at Dept. of Textile Tech. & Processing Sarvajnik College of Engg. & Technology, Surat

The instrument to be developed will be very useful to any weaving unit holder having Plain Power as well as Automatic shuttle looms. The instrument will provide on line details related to production of machine and defects in fabric to the user. Normally, in any weaving unit having shuttle looms, the unit holder will come to know about the production of machine and quality of fabrics produced only after 2-3 days i.e. after removal of fabrics from the loom. So, it will take about 2-3 days time to take any corrective measures in case of a loom/s found to produce less quantity and poor quality of fabrics. At present, there are about 20.00 lakh shuttle looms across the country. - Fabric Friction Tester Developed at Department of Textile Technology, Indian Institute of Technology (IIT), Delhi.

Photograph of developed fabric friction tester.

A new instrument is designed and developed to measure the surface friction of textile fabrics based on friction clutch principle. This instrument is designed to simulate the angular movement of human fingers over fabric, in contrast to moving fingers along principle directions of fabrics practiced in commercial instrument. The fabric friction can be measured using either smooth surface (flat aluminium) or rough surface (copper wired surface), depend on the probe selected. Instrument allows test to be conducted at user selected speed in both clockwise and anticlockwise direction with user defined normal load. The multiple probes would be used to simulate that of human fingers (as one touches the fabric with few fingers to sense the roughness/smoothness/slipperiness). - Design & Development of Electro-Active Sensor Fabrics for monitoring Body Kinematics and Vital Signs at Department of Textile Technology, PSG College of Technology, Coimbatore.

The wearable strain sensor is a unique device to measure the kinematic movements of elbow angle / knee angle. The sensor measuring 250 mm x 38 mm is built using a narrow tape woven fabric incorporating conductive threads in between as shown in Figure 1 and the measurements are shown in Figure 2. The elbow angle recording will be useful to physiotherapist / rehabilitation centre for indicating improvements in elbow angle bending over a period of time or after a critical injury. It will also be useful for continuous monitoring of the angle flexed by the elbow or knee for any research relating to arthritis. Further, measurement of knee angle goniometry will be of use for sports persons and other patients opting for knee replacement surgeries. - Online Image Processing System for Finding Size Distribution of Pellets in a Pelletization Plant at Institute of Minerals and Materials Technology, and Kalinga Institute of Industrial Technology (KIIT), Bhubaneswar.

Equipment Name: CSIR-IMMT EYE ON PELLET The “EYE-ON-PELLET” is an equipment indigenously developed which is very useful for monitoring iron ore pelletization plants. Pelletization is a process by which iron ore fines are converted to spherical balls. Normally, a human supervisor is engaged to monitor the balling shape and size for a set of pelletization discs, which leads to suboptimal performance of pellet production due to human error. However, our system is a camera based system which monitors the pellets while it is falling right at the disc and records the size distribution pattern for monitoring and future analysis. This is an aid to the supervisor of a pelletization plant.

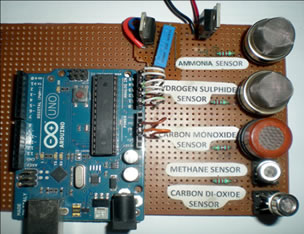

- Development of an Intelligent Recognizer for Component Analysis of Manhole Gas Mixture at Department of Computer & system Sciences, Visva-Bharati University, Santiniketan and Bengal Engineering and Science University, Shibpur

Lab scale design of portable gas mixture analysis system with Sensor array & DAS

A portable intelligent electronic system is being developed which will provide a reliable result within a few minutes whether any toxic gas is present or not inside the manhole and if so, it will raise alarm and alert the workers. A safe and sophisticated gas mixture analysis system containing a panel for toxic gas cylinders with the carrier gas cylinder, gas mixing chamber with Mass Flow Controller (MFC) and a table top furnace has been designed to analyze the sensors with mixture of gases in various concentrations to get the response of the sensors due to their target gas and also due to other gases. Some technical novelty was found in the signal conditioning unit and intelligent pattern recognition algorithms to get accurate results very quickly by overcoming the problem of cross sensitivity. Manhole gas of different areas has been collected and analyzed in laboratory by conventional chemical process and gas chromatography machine to compare with the result of sensor output. - Infant ventilator by Department of Mechanical Engineering, PSG College of Technology, Coimbatore, Tamil Nadu

A high-end infant ventilator was developed by PSG College of Technology (PSG) and Pricol Medical systems limited (PMSL) of Coimbatore. The Infant ventilator has advanced modes of ventilation to meet the dynamic needs of new-born baby and touch-screen display with attractive graphical user interface while keeping the cost of ownership at the lowest possible level without diluting the safety norms. The technology is completely indigenized to provide a better after-sales service and support. The Technology of infant ventilator was transferred to PMSL on 29th September, 2011. PMSL will launch the product during the next financial year after clinical validation, thus making the treatment of neonatal respiratory care available to a large section of the society. - Moisture evaluation with microcontroller based instrument for measuring trace moisture present in transformer oil by Electroceramics Division, Central Glass and Ceramic Research Institute (CGCRI), Kolkata-700 032

The humidity sensor devices were developed using porous ?-alumina based sensor elements. The moisture absorbed on the pores improves the dielectric property, which in turn, makes the capacitance higher at higher absorption of moisture. The objective of the work was to develop thin film porous dielectric material for detection of moisture in the range of 5-20 ppm. The sensitivity and characteristics to trace moisture has been evaluated by LCR meter and Chilled mirror hygrometer. The developed sensor calibrated an electronic device for low range moisture measurement in hand held devices for environmental and meteorological monitoring. For low range moisture detection in transformer oil application, ceramic based humidity sensor with adequate sensitivity over the moisture range from 5 to 20 ppm has been developed using a new method (sol-gel). Contract will be signed with M/s Nisha Engineering Corporation, 285/B, B.B.Ganguly Street, Kolkata 700012. They agreed to purchase humidity sensor with meter from CSIR-CGCRI. For field testing of developed prototype meters has been sent to M/s Nisha Engineering Corporation, Kolkata. - Creep Testing Apparatus for Geotextile

The main objective of the project is indigenous development of a Tensile Creep apparatus for accurately measuring this parameter strictly as per international specifications (ASTM D-5262). The equipment should be dedicated equipment and universally applicable for testing of various types of geotextiles, geogrids and geomembranes. The proposed creep tester has been developed as per the design specifications. The main features include, evaluation of extension of the test sample at two points with 100 mm gauge, continuous data record with help of data logger and computer interface for plotting of the creep curve. - Integrated Electronic Nose and Vision (EVN) System for Quality Estimation of Basmati Rice by Center for Development of Advanced Computing E2/1 Block GP, Sector-V Salt Lake Kolkata-700091.

The instrument is developed to assess the quality analysis of rice (Basmati & other varieties) in a quantitative manner and targeted for Rice producers/growers and exporters; agricultural centers/ research laboratory; food processing laboratories; food safety & quality laboratories. The Non-specific Array of Sensor (MOS based) is used in the fabrication of E-nose. The salient features include portable system for ease of field mobility, PC interfacing using USB port, instant report generation, print out facility etc. to make it user friendly.

- Continuous Feed Equipment for Extraction of Aloe Vera Gel by Central Institute of Agricultural Engineering, CIAE-Regional Centre, TNAU

The extraction equipment consists of a set of two pressure rollers on the top and a set of two rollers at the bottom on a frame above on endless belt, to flatten the aloe vera leaf fed between rollers. The gel is directly collected in the tray which is partially filled with clean water. The top and the bottom leaves are collected separately. The capacity of the equipment is about 200-225 kg/h (900- 1000 leaves/h) when motorized and 100kg/h (400-450 leaf/h) when operated manually. Saving in cost and time for gel extraction worked out 49.5 and 70% respectively. The breakeven point on number of leaves, hours of operation, days of operation, and year of operation was 164094, 195 hours, 32.5 days, and 0.135 year respectively.The machine peeled gel has lesser quantity of aloin of 1.0% when compared to 1.99% byhand peeling and was within the safe limit standards prescribed. Aloe vera leaf rind is found to be good substrate for biogas production. There is a scope for aloe vera processing industries to produce the biogas from their own industry waste. And we have conducted one sensitization workshop with the collaborative C.P. plantation industry at Kottampatty, Dindugal, Tamil Nadu.

- NIRS based on-line instrument for quality assessment in Edible Oil Industry by CEERI, CSIR MADARS COMPLEX, Traramani, Chennai-600113

Technology Awareness Meet on On-line Quality Assessment in Edible Oil Industry & On-site demonstration of the product at User Industry along with CSIR – CFTRI, User Industry and DST created higher impact to the Edible refineries, entrepreneur, & instrument manufacturers. First time a team of CSIR-CEERI have joined hands with experts from the Lipids Sciences Department of Central Food Technological Research Institute (CSIR-CFTRI, Mysore), along with supporting user industry, M/s Kaleesuwari Refinery Pvt. Ltd (manufacturer of Gold Winner Sun Flower Oil brand) who has contributed 10 %percentage of project Cos executed the project . - Design & development of improved non-electronic Soil Testing Kit with Soil Health Card and Fertilizer recommendations

The developed kit analyzes pH, Carbon, Nitrogen, Phosphorus and Potash of soil on color chart basis by chemical reactions. The kit also contains a computerized Soil Health Card for the farmers for soil quality assessment and data record for future assessment of his field and a fertilizer recommendations chart on the basis of soil characters and important crops of India. The Industrial collaborator Bio-link Overseas Co., Agra has taken up the technology for manufacturing (Photo-1, 2, 3) & marketing under the trademark “Ferticheck”. This kit is used at soil testing laboratories for qualitative assessment of soil quality. The kit is much helpful to farmers who can use it directly without any assistance and decide the health of soil and apply the suitable fertilizer and in appropriate quantity.

Performance:

- Organic carbon test. (30 minutes) Range :1 % - 7%

- Organic carbon test. (30 minutes) Range :1 % - 7%

- Nitrogen Test (2- 5 minutes) Range: 0.01% - 0.5%

- Phosphorus Test (5 minutes) Range: 0.01% - 0.4%

- Potash Test (5 minutes) Range: 0.05% - 3.5%

- pH Test (2-5 minutes) Range: 4-11

List of on-going projects:

Tenth Plan

- Project List year 2005-06

![[PDF]](/sites/all/modules/contributed/filesize_filter/icons/application-pdf.png) 5.64 KB

5.64 KB - Project List year2006-07

![[PDF]](/sites/all/modules/contributed/filesize_filter/icons/application-pdf.png) 4.5 KB

4.5 KB - Sensor Instrumentation

![[PDF]](/sites/all/modules/contributed/filesize_filter/icons/application-pdf.png) 142.62 KB

142.62 KB - Medical Instrumentation

![[PDF]](/sites/all/modules/contributed/filesize_filter/icons/application-pdf.png) 93.54 KB

93.54 KB

Eleventh Plan

| 2007-08 | 2008-09 | 2009-10 | 2010-11 | 2011-12 |

Twelvth Plan

| 2012-13 | 2013-14 | 2014-2015 | 2015-2016 |

Format and Guidelines for submission of proposals![]() 190.65 KB

190.65 KB

For more information Contact :

Dr. Neeraj Sharma

Head (TDT)

Department of Science and Technology

Technology Bhavan

New Delhi-110 016

Telefax : 011-26964781

Email: neerajs[at]nic[dot]in

| Scientist G | Scientist D | Junior Analyst |

|---|---|---|

| Dr Rambir Singh Scientist G Department of Science & Technology Technology Bhawan New Mehrauli Road New Delhi-110 016. Email:rambir.singh[at]nic[dot]in Ph:011-26590332 | Dr (Mrs) Anita Aggarwal Scientist D Department of Science & Technology Technology Bhawan New Mehrauli Road New Delhi-110 016. Email:anita[dot]a[at]nic[dot]in Ph:011-26590343 | Mrs. Rajni Rawat Junior Analyst Department of Science & Technology Technology Bhawan New Mehrauli Road New Delhi-110 016. Email:rajni[at]nic[dot]in Ph:011-26590212 |